CPQ Software for Manufacturing: Customization at Scale Made Easy

CPQ software for manufacturing streamlines customization at scale, helping manufacturers automate quotes, pricing, and configurations with ease.

In todays dynamic manufacturing landscape, customer expectations have evolved dramatically. Buyers now demand tailor-made products, fast turnarounds, and transparent pricingall without sacrificing quality or cost. Meeting these expectations requires more than just operational efficiency; it demands smart digital transformation.

Enter CPQ softwareshort for Configure, Price, Quotea game-changer that allows manufacturers to scale customization without complexity. Whether you're producing industrial machinery, electronics, or modular furniture, CPQ software can help you meet customer demands while improving speed, accuracy, and profitability.

What Is CPQ Software?

CPQ (Configure, Price, Quote) software is a digital sales tool that helps companies:

-

Configure complex products or services based on customer requirements.

-

Price them accurately, considering costs, discounts, and margins.

-

Quote the customer with automated, professional documentation.

For manufacturers, CPQ software bridges the gap between engineering, sales, and productionmaking it easier to offer mass customization without slowing down operations or introducing costly errors.

Why CPQ Matters for Manufacturers

Traditional quoting and sales processes in manufacturing are often fragmented, manual, and error-prone. Sales reps must rely on spreadsheets, tribal knowledge, or slow back-and-forths with engineering teams.

Heres where CPQ shines:

1. Faster Time to Quote

CPQ platforms automate configuration and pricing in real time. This allows sales teams to generate quotes within minutes instead of daysspeeding up the sales cycle and increasing win rates.

2. Error Reduction

Manual configurations can easily result in incompatible components or pricing errors. CPQ ensures rules-based configurations, eliminating mistakes that lead to rework, delays, or customer dissatisfaction.

3. Scalable Customization

With CPQ, you can offer thousands of product variations without adding complexity. Whether its a new material, size, or feature, CPQ platforms handle it seamlessly through configurable logic.

4. Improved Customer Experience

Customers receive accurate, detailed, and visually rich quotesoften including 3D models, product visualizations, and pricing breakdowns. This builds trust and makes decision-making easier.

5. Integration with ERP & CRM

Modern CPQ tools integrate with ERP and CRM systems, ensuring a unified workflow from quote to order to productionwithout redundant data entry or delays.

Use Cases of CPQ in Manufacturing

Lets explore how CPQ software supports real-world manufacturing needs:

1. Industrial Equipment Manufacturers

Companies producing heavy machinery often face the challenge of configuring machines for unique client specs. CPQ software for manufacturing helps them quickly create configurations based on load capacity, power, attachments, etc., while calculating the exact price including custom add-ons.

2. Electronics & High-Tech Manufacturers

From custom PCBs to smart devices, CPQ simplifies the pricing of components, options, and bundles, ensuring faster quote turnaround with precision.

3. Furniture and Modular Product Makers

Manufacturers of customizable furniture or modular solutions benefit from CPQs visual configuration capabilities. Users can drag-and-drop features, visualize outcomes, and instantly see pricing changes.

4. Automotive & Transportation Equipment

CPQ allows car or truck manufacturers to offer complex build-to-order options (e.g., engine types, interiors, tech packages) while maintaining production accuracy.

Key Features to Look for in CPQ Software for Manufacturing

Choosing the right CPQ platform is crucial. Here are the must-have features tailored for manufacturers:

1. Product Configuration Engine

A powerful rules engine allows for logic-driven configurations. It ensures only valid product combinations are offered, reducing costly mistakes.

2. Visual Configuration

Visual CPQ tools help customers and sales reps see the final product in real-time, enhancing clarity and satisfaction.

3. Pricing Automation

From cost-based pricing to margin control and discounts, CPQ automates every pricing scenario, keeping your profits protected.

4. BOM (Bill of Materials) Generation

Automatically generate BOMs based on selected configurations. This accelerates handoff to production and ensures consistency.

5. Integration with CAD & PLM

Advanced CPQ tools integrate with CAD software to pull in technical details and drawings, ensuring engineering accuracy.

6. Mobile & Cloud Accessibility

Modern CPQ tools offer cloud-based access so sales teams can quote from anywhereon the shop floor, at a trade show, or from a customer site.

Benefits of Implementing CPQ in Manufacturing

1. Accelerated Sales Cycles

With quick quote generation and real-time feedback, CPQ reduces the time it takes to move from inquiry to order.

2. Higher Win Rates

Fast and accurate quotes improve customer confidence and increase close rates.

3. Reduced Operational Costs

By automating manual tasks and reducing errors, CPQ lowers labor costs and rework expenses.

4. Enhanced Data Insights

Track which configurations are most popular, pricing trends, and win/loss analysis to fine-tune your offerings and pricing strategies.

5. Competitive Advantage

Offering mass customization at scalewith no compromise on delivery timecan set your business apart in a competitive market.

CPQ and the Future of Smart Manufacturing

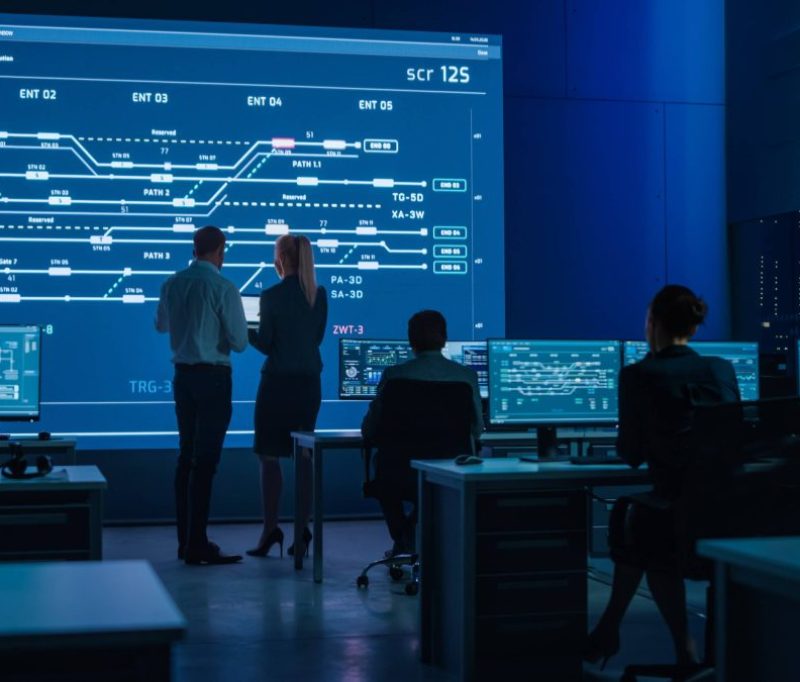

As Industry 4.0 continues to evolve, CPQ software is becoming a cornerstone of smart manufacturing. It not only enhances front-end sales processes but also feeds into digital twins, predictive maintenance, and agile supply chains.

With AI and machine learning being integrated into modern CPQ systems, future capabilities may include:

-

AI-assisted pricing optimization

-

Predictive sales recommendations

-

Automated engineering drawing generation

-

Real-time inventory and supply chain visibility

How to Get Started with CPQ in Your Manufacturing Business

Ready to implement CPQ? Heres a quick roadmap:

-

Define Your Sales and Configuration Challenges

Understand where the bottlenecks are in your current quoting and configuration process. -

Map Product Configuration Rules

Work with engineering and sales to map out valid configurations and pricing logic. -

Select the Right CPQ Vendor

Look for a vendor experienced in your industry, with strong integration capabilities and manufacturing-specific features. -

Train Sales and Engineering Teams

Ensure teams understand how to use the system effectively and provide feedback during rollout. -

Start with a Pilot Program

Test the CPQ system with a small team or product line before scaling across the organization.

Conclusion

Mass customization no longer needs to be a logistical nightmare. With the right CPQ software, manufacturers can deliver personalized products at scale, streamline operations, and boost customer satisfactionall while protecting their bottom line.

In a world where customer demands are rising and competition is fierce, CPQ offers a powerful way to stand out, move faster, and sell smarter.